Buy Premium Dual-Cure Silk Screen Printing Photosensitive Emulsion

$50.99

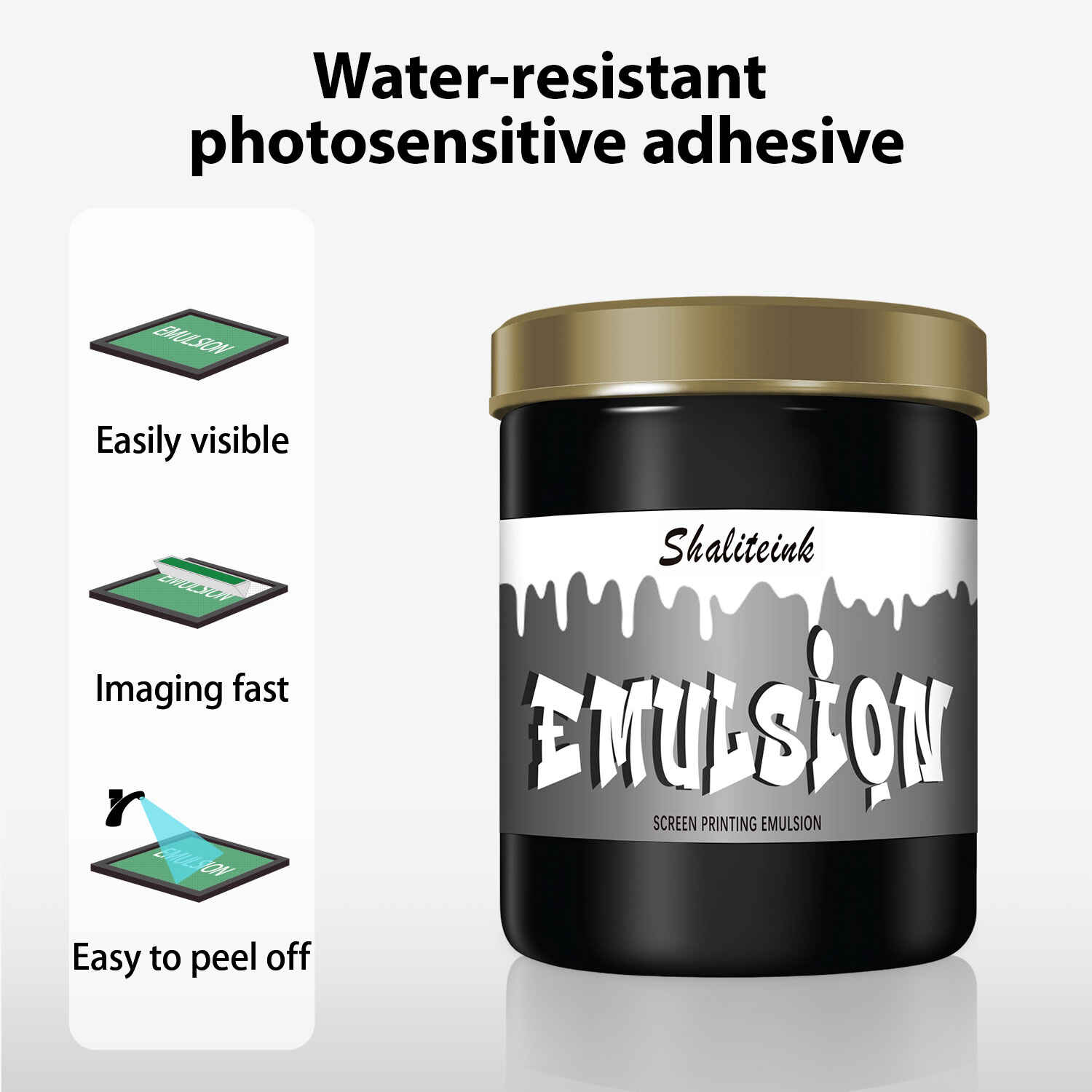

This high-quality photosensitive emulsion for Screen Printing is designed specifically for screen printing and is easy to use. It dries quickly and captures detail, allowing you to easily transfer your designs to the screen—ideal for DIY projects, workshops, or professional printing.

If you’ve spent as much time in a darkroom as I have, you know the sinking feeling of a stencil breaking down halfway through a rush order. It’s the nightmare scenario: stopping the press, reclaiming the screen, recoating, drying, and burning it all over again. That’s why we know that while ink gets all the glory, your photosensitive emulsion is the unsung hero of the shop. It is the foundation of every crisp line, every halftone dot, and every profit margin.

We have formulated this premium emulsion to be the daily workhorse for professional print shops. Whether you are running an automatic press at high speeds or manually pulling squeegees in a garage setup, this emulsion offers the latitude, durability, and resolution you need to keep production moving.

Silk Screen Printing Photo Emulsion Specifications

Here is the technical breakdown for the shop managers and supply purchasers:

| Feature | Specification |

| Type | Dual-Cure (Diazo + Photopolymer) |

| Color | Blue/Violet (High contrast for easy registration) |

| Solids Content | 40% – 42% (High resolution, sharp edges) |

| Viscosity | Medium-High (Approx. 8,000 – 10,000 cps) |

| Sensitizer | Diazo Powder (Included – Add water to activate) |

| Pot Life | 4-6 weeks after mixing (Keep cool) |

| Shelf Life (Unmixed) | 12+ months |

| Exposure Speed | Fast (Variable based on light source) |

| Compatibility | Plastisol, Water-based, Discharge, Solvent, UV Inks |

| Reclaimability | Excellent (Dip tank compatible) |

Product Advantages Summary

-

High-Solids Formula: Delivers sharper edges and better mesh bridging for superior print definition (EOM).

-

Universal Compatibility: withstands standard plastisols, aggressive PVC free plastisol ink, water-based, and discharge systems.

-

Durability: Engineered for long production runs without stencil breakdown or pinholing.

-

Fine Detail: Excellent resolution for halftones and plastisol cmyk ink process printing.

-

Easy Reclaiming: tough on press but dissolves quickly with remover, extending the life of your mesh.

The Chemistry Behind the Magic

Let’s talk specs, but keep it real. This is a high-solids, dual-cure hybrid emulsion. Why does that matter to you?

In the old days, you had to choose. You either picked a Diazotype for water resistance (but it was slow to expose) or a pure Photopolymer for speed (but it was brittle). We’ve bridged that gap. By combining the best resins, we’ve created a product that exposes fast enough to keep your workflow efficient but retains the toughness required to withstand long runs.

The high solid content (approx. 40-42%) means less shrinkage as it dries. When the water evaporates during drying, you are left with a thicker, smoother stencil gasket (EOM). This is crucial for preventing “sawtooth” edges on your prints. A better gasket means the ink sits on top of the shirt, not driven into the fibers, giving you that bright, opaque pop we all chase.

Universal Ink Compatibility

One of the biggest headaches in a diverse shop is stocking three different tubs of goo for different jobs. This formula is designed to be universally resistant.

You might run standard plastisol ink. It works for athletic gear. It works for t-shirts. This emulsion is bulletproof. Cheap stencils get soft. The plasticizers eat them up. This emulsion fights that off. It is long-lasting. But the industry is changing. Clients want a soft hand. They want eco-friendly options. If you are making the switch to PVC free plastisol ink, which can sometimes be chemically aggressive in different ways than traditional plastisol, this emulsion holds its structure perfectly without becoming tacky or slimy during the run.

Furthermore, for those of you venturing into water-based printing or discharge inks, this dual-cure formula—once hardened—offers excellent water resistance. It won’t turn to slime in the wash tank or break down under the friction of water-based squeegees.

Precision for High-End Detail

Are you tired of losing your 5% dots? The resolution capabilities of this emulsion are top-tier. When you are dealing with plastisol cmyk ink for photorealistic process printing, every single dot counts. If your emulsion can’t bridge the mesh threads properly, you get moiré patterns and muddy images.

Our formula has excellent “mesh bridging” capabilities. It fills the gaps between your threads to create a perfectly flat surface for the ink to shear against. This allows for incredibly fine detail, making it the ideal choice for simulated process jobs, fine text, and intricate halftones.

Handling the Heavy Stuff

Not every job is a soft-hand vintage print. Sometimes, you need to lay down thick deposits. Whether you are printing puff, high-density, or using coarse mesh for glitter, you need a stencil that builds up fast.

Because of the high viscosity, this emulsion coats like a dream. It sits on the screen rather than dripping through the mesh. You need a thick stencil for specialty inks. Think about glitter or shimmers. The flakes are big. They need room to pass through. You have to build up the emulsion. This product makes that easy. Some inks are rough on screens. They are abrasive. But this stencil gets hard. It takes the abuse. Your prints stay sharp. The first shirt looks great. The 500th shirt looks the same.

Application and Darkroom Tips

Look, I’ve coated thousands of screens, and I know that “user error” is usually just “finicky product.” We designed this to be forgiving.

-

Coating: It has a medium viscosity. It doesn’t drip off your scoop coater, but it flows smooth. A standard 1/1 (one coat print side, one coat squeegee side) works for 80% of jobs. For high-density work, a 2/1 method builds a beautiful stencil.

-

Drying: This is where many fail. Keep your humidity under 40%. This emulsion dries relatively fast, but ensure it is bone dry before exposure to avoid “scumming” during washout.

-

Exposure: It has a wide exposure latitude. This means if your calculation is off by a few seconds, you won’t ruin the screen. It helps you avoid those dreaded pinholes caused by underexposure, or the loss of detail caused by overexposure.

-

Reclaiming: Despite its durability on the press, we know you don’t want to spend 20 minutes scrubbing a screen at the washout booth. It breaks down easily with standard emulsion removers, saving your mesh for the next job.

Troubleshooting Common Issues

Since we are talking shop, let’s address common issues this emulsion helps solve:

-

Pinholes: Usually caused by dust or fast coating. Because this emulsion has high solids, it creates a stronger barrier that is less prone to pinholing than cheaper, watery alternatives.

-

Fish-eyes: The flow characteristics of this fluid minimize cratering, provided your degreasing game is on point.

-

Premature Breakdown: If you find stencils breaking down with aggressive solvents or specialty ink, you can post-expose (leave the dried, washed-out screen in the sun or UV light) to chemically lock the stencil for extreme durability.

Why This Matters for Your Business

In the wholesale market, you aren’t just buying chemicals; you are buying consistency. You need to know that the bucket you buy in January performs the same as the one you buy in July. We maintain strict quality control to ensure batch consistency.

Whether you are stocking up for a massive contract order involving complex screen printing ink systems or you are a supplier looking for a reliable house brand, this photosensitive emulsion delivers the performance required by modern textile decorators. It allows you to say “Yes” to more jobs, regardless of the ink type or artwork complexity.

FAQ

Q: How long does this emulsion last once I’ve mixed it?

A: Once sensitized, you generally have a “pot life” of 4 to 6 weeks. However, you can extend this significantly by keeping the bucket in a cool place. If you have a shop fridge (not the one with your lunch!), storing it there can keep it fresh for 2-3 months. Just make sure to let it warm up to room temperature before coating, or your viscosity will be off.

Q: What is the correct exposure time for this emulsion?

A: I cannot give you a magic number. It depends on your lights. Maybe you use LED. Maybe you use Halogen. Your mesh count changes things too. This formula is high-solids. It takes a few seconds longer. Pure photopolymer is faster. But the wait is worth it. The detail is sharp. We highly recommend using a generic “step wedge” calculator for your first screen to dial in the perfect time for your setup.

Q: Is this emulsion water-resistant enough for discharge printing?

A: It sure is. It handles standard ink well. It works with plastisols right away. But some inks are harsh. Water-based inks are tough. Discharge inks are tough too. You should post-expose the screen. Wash out your image first. Dry the screen. Put it back in the sun. Or put it under UV lights. Give it 5 to 10 minutes to locks the stencil. It gets very hard. Water friction will not hurt it.

Q: Why is my image washing out slimy on the inside (squeegee side)?

A: That looks like under-exposure. The UV light did not get all the way through. It did not hit the squeegee side. You need more burn time. Maybe the coating is too thick. The light struggles to penetrate. A 1 over 1 technique works well. You coat the print side once. You coat the squeegee side once. This layer is consistent. It is easy to expose.

Only logged in customers who have purchased this product may leave a review.

Reviews

Clear filtersThere are no reviews yet.